MODEL IDENTIFICATION

This page has highlights of the history of our cars. For a comprehensive history, a book has been written by our Club Historian, Sam Roberts. Details of the book can be found by using this link Ford Models Y & C - Henry's Cars For Europe

(Click on pictures to enlarge)

Dearborn (U.S.A.) Manufacture Model 19 prototype

Model 19 prototype

14 prototype 8 h.p. Ford saloon cars were designed, built and shipped to England over a period of only four months from 19 October 1931. They were unveiled at the Royal Albert Hall on 19 February 1932 and were also displayed in other European capitals. The cars were concept cars, unable to be driven, but heralded the entry of Ford into the European small car market. They were all destroyed at the end of 1932.

Model 19/Model “Y” pre-production model

In parallel with the prototype cars, the in-service cars (Model 19) were being designed and built at Dearborn. Eleven were trialled and developed in the Ford Engineering Laboratory and on the Dearborn test track against imported English small cars. A twelfth (pictured) was shipped to England in March 1932 and registered EV 5689. This was used for test purposes at Dagenham and for promotional brochure and advertisement work. It can be recognised by the 10 louvres on the bonnet side and the Model A door handles. The title, Model “Y”, was adopted on 6 July 1932. Later, a pre-production four door version was received in Dagenham but was not registered. One of the development cars is known to have survived in Detroit.

Dagenham (UK) Manufacture

Model “Y” short radiator (short rad) saloon. August 1932 – end September 1933

Early short rad Model “Y”

Production of the Model "Y" commenced at Dagenham on 10 August 1932. Initially, only two-door (Tudor) models were made, the four-door (Fordor) not being produced before 22 September. Although there were a number of design changes over the following year, the ‘short rad’ can be easily recognised by the nine louvres on the bonnet side, the straight, ribbed bumpers, the radiator grille too short to include a starting handle hole (this was in the front valance below the grille), ‘diamond’ shaped door handles and the mudguards without trailing skirts. A total of 26,895 short rads, including 2209 Fordor De Luxe, were built, many for export (LHD cars were built w.e.f. December 1932). The plucky little 933 cc sidevalve engine produced 22 brake horse power.

Model “Y” long radiator (long rad) saloon. October 1933 – 13 August 1937

‘Intermediate’ long rad Model “Y”

This was Eugene Gregorie’s final styling for the Model “Y” which Edsel Ford had scaled up to become the V8 Model 40. The more ‘streamlined’ look incorporated only six louvres on the bonnet side, a deeper V shaped radiator grille with a hole for the starting handle, a dipped single-grooved front bumper and straight single-grooved rear bumper, mudguards with valance ‘skirts’ behind the wheels and ‘art deco’ streamlined door handles. The more obvious visual changes during the production of the earlier ‘Intermediate’ long rad models included the replacement of the central piano- type bonnet hinge by a chrome strip hinge; the change from an engine-turned instrument panel inserted in one of the glove compartment spaces (depending on whether R.H.D. or L.H.D.) to a centrally located set of instruments in a black one-piece dashboard and improvements to the front lights, which finally resulted in combined side and head lights with a diamond shaped Magniflex bar. On the introduction of the De Luxe Model “C” in September 1934, the Model “Y” became known as the “Popular”. From this date, no further De Luxe Model “Y”s were manufactured. In October 1935, the price of the Tudor Model “Y” was reduced to £100, the first and only saloon car to ever be sold at that price. It was raised to £105 from 1 July 1937. A total of 108,343 Tudor and Fordor long rad Model “Y”s were manufactured at Dagenham. As with the short rad, many were shipped in Completely Knocked Down (CKD) state in crates to the various European and Empire Ford assembly plants (note:- short rad bumpers were fitted to export long rad cars (less those to the Irish Free State) until the surplus stock of short rad bumpers was exhausted –approx. April 1934)

Two-door (Tudor) long rad Model “Y” ‘Popular’

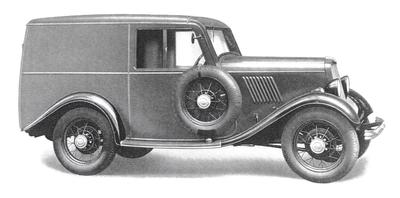

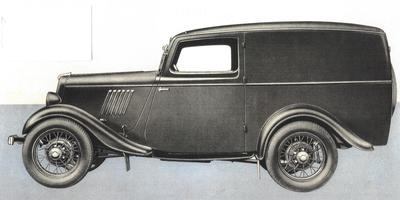

Model “Y” short rad 5 cwt van. 14 November 1932 – October 1934

Early large door short rad van

Some 3,034 8 h.p. 5 cwt short rad vans were built, production starting on 14 November 1932. Initially (Briggs body numbers 121/---) they had running boards, front bumpers, a large door on the near side and the spare wheel mounted on the off-side running board (hence no door on the driver’s side). From 12 June 1933, (Briggs body number 126/---) the running boards were discontinued to aid mounting and dismounting (a mud flap was added to the rear of the front wings), a smaller door was introduced and the spare wheel was mounted on the off-side door, which now opened. From 22 November 1933 (Briggs body number 128/-) the front bumper was discontinued to reduce weight for taxation purposes.

Small double entrance short rad van

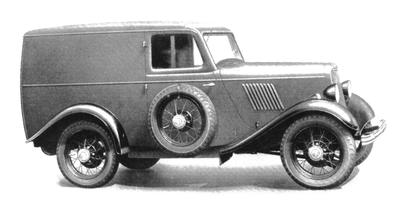

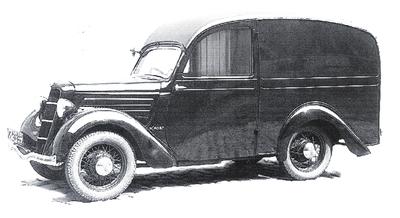

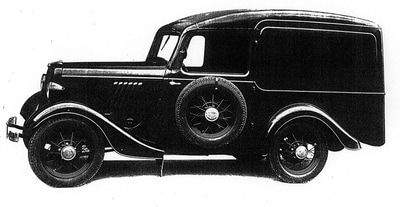

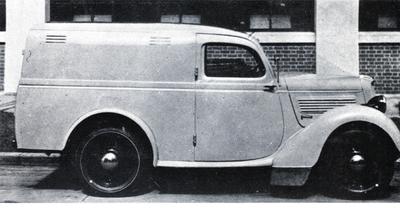

Model "Y" long rad 5 cwt van. October 1934 - 30 November 1937

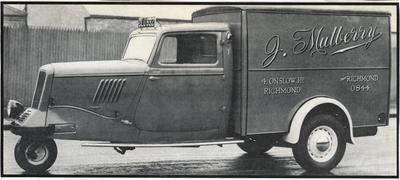

The improvements to the long rad 5 cwt van styling reflected the changes introduced on the long rad saloon. Additionally, the front bumper was dispensed with and longer mud flaps were attached to the rear of the front wings. Separate side lights remained in production well after they were discontinued on the saloon, to use up surplus stock. The short rad ‘diamond’ shaped door handles were retained on the van through to the end of production on 30 November 1937, a total of 26,572 long rad vans having been manufactured. The spare wheel was moved from the off-side door to the near-side door in October 1936. Note:- the Model “Y” van was never manufactured with rear windows, only with three horizontal air vents in each of the rear doors. A number of vans were converted to pick-ups, either by professional coachbuilders or privately. Some conversions to ‘woodies’ are also known.

Long rad van converted to pick-up

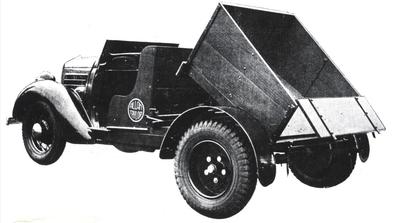

Model “Y” Tug and Allan Taylor tractor

Model “Y” Tug

Launched in October 1935, the Tug was a three wheeled ‘mechanical horse’, approved and marketed by the Ford Motor Company, and designed and built at County Commercial Cars Ltd., Fleet, Hampshire, using Model “Y” engines and ancillaries and body parts from Dagenham (Briggs body number 161/---). Available as a tractor with or without a two or four wheeled trailer. Not a successful venture; only 111 vehicles were manufactured, although 121 bodies were made by Briggs. County Commercial Cars also marketed a three-wheeled van based on a similar design called the ‘Devon’, the Tug having originally been named ‘Dorset’ by the company.

County Commercial Cars Ltd. Devon van

Allan Taylor’s 8 hp groundsman’s tractor

Another Model “Y” tractor was manufactured and marketed by the Allan Taylor Engineering & Manufacturing Co. of Wandsworth, London. This was primarily designed for general duties on sports fields and for pulling gang mowers.

Model “Y” special bodied cars

The launch of the Model “Y” coincided with the depth of the Great Depression following the Wall Street Crash of 1929. Money was scarce and Ford dealers faced major competition from traditional English makes. Their plight was not helped by Ford’s decision not to make an open-topped version of the Model “Y” as it was felt that, with a ladder-type chassis, the doors would fly open and the rigidity provided by an enclosed body was the only answer. In order to attract potential customers into their showrooms, the major dealers purchased rolling chassis from Dagenham and commissioned local coachbuilders to produce attractive open-topped bodies. As the coachbuilders were also suffering in the Depression, they were only too willing to take on the work. Some 24 different body styles have been identified. The more attractive ones created a demand and were sold in significant numbers, some of which have survived. The introduction of the cheaper, massed-produced Morris 8 Tourer in 1934 killed off the demand for these relatively expensive hand-built specials. Survivors include:-

Abbey Tourer

Built by Abbey Coachworks Ltd. of Merton and Acton.

Arrow Alpine sports tourer and the standard tourer

Built by Arrow Coachworks of Hanwell, West London and marketed by W.J. Reynolds (Motors) Ltd. of East Ham, London.

Cairn coupé

Built by Salmons & Sons Ltd. and the Terrier sports tourer (renamed the Kerry w.e.f. July 1933), built by Whttingham & Mitchel Ltd. of Kings Road, London, were marketed by W. Harold Perry Ltd., North &Sons Ltd. Tickford ‘Cairn’ coupé.

Terrier/Kerry sports tourer

Built by Whittingham and Mitchel.

Mistral tourer

Built by Jensen Bros. Ltd. of West Bromwich and marketed by Bristol Street Motors, Birmingham.

Special - Rear Door Saloon

A speciality of J.H. Jennings & Son, Ltd., Motor Body Builders of Sandbach, Cheshire, was to cut out the rear of a standard saloon car and replace it with a door. With the rear seats removed and a false floor inserted, under which was stored the spare tyre, a useful car cum van was created. A number of Tudor Model “Y”s were converted to ‘utility’ cars, one of which is known to have survived, having spent much of its useful life in the Sudan.

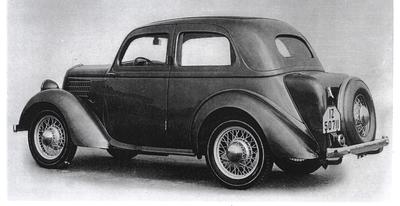

The 10 H.P. De Luxe Model “C” Saloon. 10 September 1934 –11 November 1935

Four-door (Fordor) Model “C” saloon

The trend towards manufacturers bringing out new replacement models every two years had taken hold in America by the early 1930s. It was Ford headquarters’ plan to replace the Model “Y” in Europe in 1935 with a new model. Because of the success of the Model “Y” and because of the cost of re-tooling the production line for a new model at the cash-strapped Dagenham, Sir Percival Perry convinced Ford headquarters in Dearborn to continue production of the 8 h.p. Model “Y” and manufacture the proposed successor, a 10 h.p. Model “C”, on the same production line. Perry had seen the drawings for the 1935 V8 (Model 48) during his visit to Dearborn in November 1933 and had asked for its design details with a view to scaling them down for the proposed Model "Y" successor. The basic design, without any chrome embellishments, was unveiled at the Ford Dealers’ Convention at Blackpool on 17th September 1934. The Model "Y" and the Model "C" were marketed as the Ford “Popular” and the Ford "De Luxe". Thereafter, no further De Luxe Model “Y”s were manufactured. The Model “C” took ‘streamlining’ up a notch, with no running boards and a teardrop-shaped rear. It was a wider car than its predecessor but, because of its bulbous shape, it was known in the vernacular as the ‘Barrel Ford'. It boasted a larger 1172cc sidevalve engine producing a further 10 brake horse power (32.5 b.h.p.) over the Model “Y”. The Model “C” had a plain radiator grille and horizontal louvres on the bonnet sides. Neither carried any chrome strips. Tudor and Fordor versions were available, with and without a sliding roof. A total of 17,244 Model “C” De Luxe saloon cars were manufactured during the 14 months of its production.

10 hp De Luxe Model “CX” Saloon. 14 October 1935 – 22 March 1937

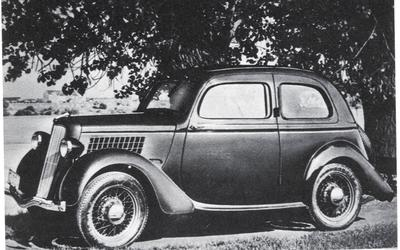

Two-door (Tudor) Model “CX” saloon

The 112 inch wheel-base 1935 V8 Model 48 (Model 60 in England) was introduced in the U.S.A. in December 1934, three months after the unveiling of the Model "C". It was for this reason that the Model "C" did not look as glitzy as the Model 48. However, similar chrome embellishments to the Model 48 were added to the Model “C” and, with a few additional minor changes, the Model “CX” was launched at the Ford Motor Exhibition at the Royal Albert Hall on 17 October 1935. Four equally spaced chrome strips (chevrons) now adorned the radiator grille and three horizontal chrome strips gave a more ‘streamlined’ look to the bonnet sides, which now had vertical louvres along their length. The main change inside the car was the move of the traffic indicator switch from the gear lever to the steering wheel and the addition of a central clock on the dashboard, rather than a small clock in the rear view mirror. Despite its lively performance, the public did not take to the design and sales started to drop off at the end of 1936. Production of the saloon was transferred on 22 March 1937 from the “CX” to the English designed 10 hp 7W. A total of 27,940 Model “CX” saloons were manufactured. Many were exported in crated CKD condition, especially to Copenhagen, Barcelona and Lower Hutt, New Zealand. Some 3,500 rolling chassis in KD condition were also exported to Australia, where they received bodies indigenous to that country.

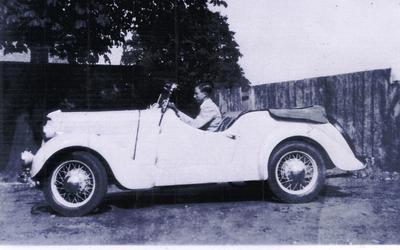

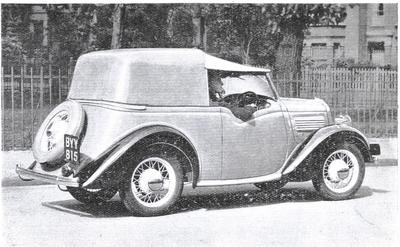

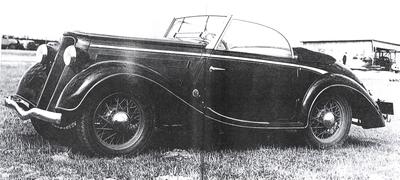

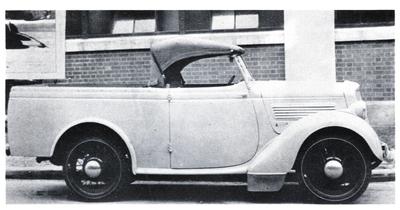

10 hp De Luxe Model “C” And “CX” Tourers. 2 May 1935 – 1 March 1937

Model “CX” tourer

Because the Model “C” chassis was of a more rigid design than the Model “Y”, a 10 hp tourer was manufactured at Dagenham, using the same transmission and body styling and panels, where possible, as the saloon car. It filled a niche in the market between the up-to 1000 cc and the six cylinder/V8 sports cars cum tourers and its pleasing lines and lively performance enhanced its attraction. Coming into production late in the day (2 May 1935), the Model “C” tourer only sold 1068 cars before it was replaced by the Model “CX” tourer on 25 January 1936. The Model “CX” was not much more successful, selling only 1795 cars before its demise on 1 March 1937. Because the tourer did not suffer the effects of the rust trap caused by the less than waterproof rear windows in the saloon version, a relatively large percentage of tourers has survived. It remains a very attractive car.

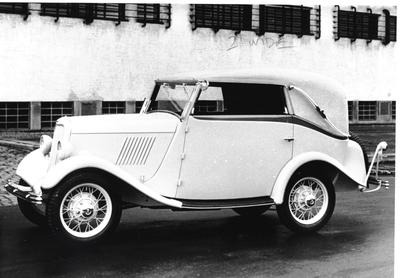

Model “C“ / “CX“ Special Bodied Vehicles

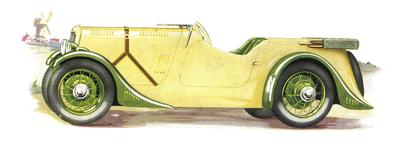

Jensen Bros. Ltd. Model “CX” ‘Hurricane’ sports tourer

Jensen Bros. Ltd. of West Bromwich built two smart bodies on the 10 hp rolling chassis. A 4-seater sports body, called a Hurricane, in both the Model “C” and “CX” form, and

a close-coupled Drop Head Coupé on the “CX” chassis:-

a close-coupled Drop Head Coupé on the “CX” chassis:-

These were marketed through Bristol Street Motors

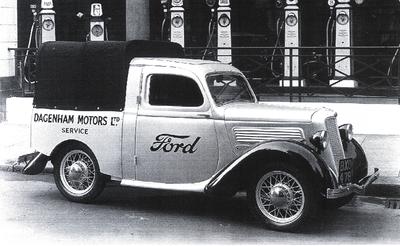

Model “CX” van

Dagenham Motors Ltd. of Balderton Street, London, commissioned both van and pick-up bodies on the Models “C” and “CX” chassis.

Allan Taylor Ltd. ‘Coronation’ groundsman’s tractor Groundsmans Tractor

Allan Taylor Engineering & Manufacturing Co. Ltd. of Wandsworth, London, produced a groundsman’s general purpose ‘Coronation’ tractor based on the front end of the Model “CX” with 10:1 gearing on a special back axle. They also produced a commercial traveller’s, or trader’s detachable roof for the Model “C”/ “CX” tourer, on which Allan Taylor Ltd. detachable roof for Model “CX” tourer.

Allan Taylor Ltd. detachable roof for Model “CX”

German Manufacture and Assembly

Model “Y”/ Ford Köln

Cologne manufactured Köln limousine bodied by Ambi-Budd

Under the ‘1928 Plan’, Dagenham was to ship Model “Y” cars in CKD state from the River Thames jetty at Dagenham to Ford assembly plants situated either on the sea or on navigateable rivers in the major European countries. The German Ford assembly plant sat on the River Rhine at Cologne. Initially, Model “Y”s were shipped and assembled in Cologne, but Adolf Hitler, who had become Chancellor in the Reichtag in January 1933, decreed that cars sold in Germany should be manufactured in Germany with German components. As a result, drawings were re-worked to read metric measurements and German body and component manufactures were contracted to supply the Ford factory in Cologne. Because of the changes in production, there were differences in specifications, e.g. engine capacity now rated at 921 cc. The car was renamed the Ford Köln and appeared with a variety of body styles. The standard saloon (‘limousine’ in German parlance) was a Tudor with a body by Ambi Budd in Berlin. There was a cabrio-limousine bodied by Drauz and cabriolets bodied by Drauz, Gläser and Deutsch. The Ford Köln limousine can be differentiated from the English Model “Y” by its lack of running boards, mud flaps at the rear of the front wings and bumpers without grooves (the imported early short rads had straight ribbed bumpers). Built up Model “Y”s (short rads) were imported from Dagenham between January and 30 April 1933; CKD Model “Y”s were imported between May and July 1933 and assembled in Cologne and the Cologne manufactured Ford Kölns were produced between August 1933 and September 1936. A total of 276 Model “Y”s were imported and a total of 10,050 Ford Kölns (including Volkstyp – see below) were manufactured. The 4/21 PS nomenclature often accompanying the Ford title refers to 4 fiscal horsepower (Pferd Stärke).

Köln cabrio-limousine bodied by Drauz

Drauz bodied Köln cabriolet

Gläser bodied Köln cabriolet

Deutsch bodied Köln cabriolet

Hebmüller bodied cabriolet

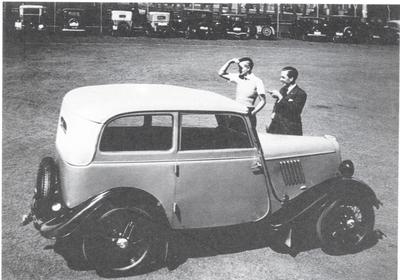

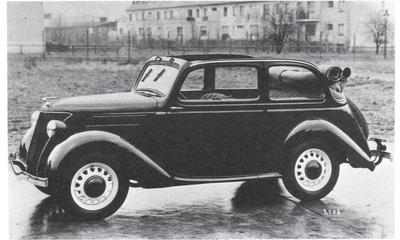

Ford Köln – Volkstyp. May 1933 – August 1935

The cheap Köln ‘Volkstyp’ to meet Hitler’s demand

Adolf Hitler’s dictum that all motor manufacturers should strive to build a cheap car for the people (‘Volkswagen’), resulted in Ford’s contribution, the Köln, ‘Volkstyp’. This two-door, four-seater cabrio limousine, on a basic Ford Köln chassis and transmission, was given a fabric on plywood body tub manufactured by Traut. To keep costs down, it had no running boards or bumpers. None is known to have survived.

Ford 4/21 PS Expresslieferwagen

The Köln ‘Leiferwagen’ (delivery van)

A delivery van body was also available on the Ford Köln chassis. Characteristics included no running boards and mud flaps to the rear of the front wings, a front bumper, standard limousine doors, a single rear door on which was carried the spare wheel. None is known to have survived.

Ford Eifel February 1935 – October 1936

1935 Eifel limousine with Model “C” bonnet features

Initially, 186 CKD Model “C” vehicles were imported from Dagenham and assembled in Cologne. They can be differentiated from the Dagenham assembled cars by the Eifel badge on the radiator grille. From 21 April 1935, German built Eifel cars, similar in body style to the Model “C” were manufactured in Cologne. The cars, all Tudors, can be identified by four horizontal chrome strips on 11 wide vertical louvres on the bonnet sides. As with the Ford Köln, there was a limousine with and without boot ["Koffer"] bodied by Ambi-Budd and a 4-seater cabrio-limousine bodied by Drauz, two different 2-seater cabriolets by Deutsch and two roadsters by Stoewer and Hebmüller. A total of 9,881 of these early Eifels were manufactured.

1935 Eifel limousine with ‘Koffer’ (boot)

Early Eifel cabriolet bodied by Gläser, 1935

Early Eifel cabriolet bodied by Gläser, 1936

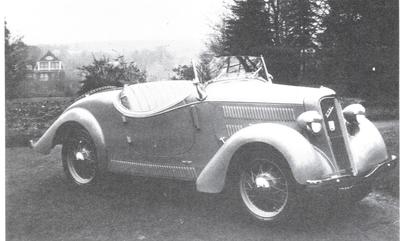

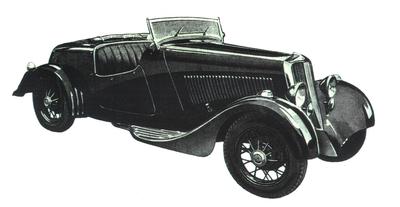

Early Eifel sport roadster bodied by Stoewer, January - May 1936

Early Eifel sport roadster bodied by Hebmüller, May - October 1936

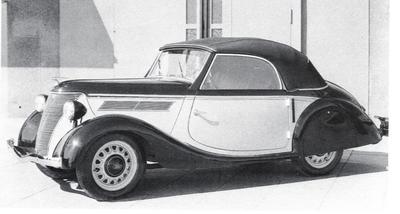

Ford Eifel – October 1936 – May 1938

Minor changes in the body design resulted in a more modern and sleeker looking Eifel. The Model “C” radiator grille was replaced with a V grille, copied from the British V8 Model 62 of 1936. The bonnet sides, which carried narrow rows of six horizontal louvres inside two chrome strips, were attached to the bonnet lid, the whole being locked by handles at the front of the bonnet sides and raised about a hinge at the scuttle, known as 'Alligator' bonnet. The wire-spoked wheels were replaced with the more modern pressed steel type. In addition to the limousine bodied by Ambi-Budd, there was a cabrio-limousine by Drauz, a 4-seater, a 2-seater cabriolet and a roadster bodied by Deutsch. All were Tudors. A total of 18,134 of these ‘interim’ Eifels were manufactured.

1937 Eifel limousine with 'Alligator' bonnet

|

Bonnet style w.e.f. February 1936

|

1937 Eifel cabrio-limousine with ‘alligator’ bonnet

Late 1936 Eifel roadster bodied by Deutsch

The styling of the final Eifel differed little from the ‘interim’ model described above, other than the design of the bonnet, which now had a separate bonnet lid which opened ‘alligator’ style using the winged mascot at the front as a locking device. The bonnet sides remained in situ. 33,483 vehicles of this type (including Roadsters – see below) were manufactured, made up of a limousine by Ambi-Budd, a cabrio-limousine by Drauz and a 2-seater cabriolet by Deutsch, Gläser and Karmann.

1938 Eifel cabriolet bodied by Deutsch

|

Bonnet style w.e.f. May 1938

|

Ford Eifel Roadster. September 1936 – 30 April 1939

In January 1936 the first Roadster was launched, bodied initially by Stoewer, with two rows of horizontal louvres on the bonnet side (similar to Jensen Model “Y”s) and vertical louvres along the underside of the doors (similar to the Model “Y” Kerry). From May 1936, cars were bodied by Hebmüller with pressed steel panels from Ambi-Budd. These early roadsters carried the Model “C” radiator grille. In September 1936 a very attractive 2-seater Roadster with a V grille, bodied by Deutsch with panels made by Ambi-Budd, was introduced. The styling became more ‘streamlined’ throughout its production life. Initially, during the production period of the February 1937 'alligator' bonnet the tops of the doors included a dip for resting the arms. With the introduction of the May 1938 'alligator' bonnet these were replaced by straight tops, resulting in a beautiful smooth body line from the front to the large attractive beetle-back type rear, on which was carried the spare wheel, initially proud of the surface and then, latterly, sunken. A truly beautiful

1938 Eifel roadster

Ford Eifel Not-Schlepper (auxiliary tug) 1940

Due to the war tugs and lorries were confiscated for military service and there was a need of hauling capacity. Therefore in1940 auxiliary axles were built those Ford Eifel which were not drawn into military service during WW II. These axles were attached to an auxiliary frame. A chain sprocket wheel attached to the brake drum to get a shorter ratio. The maxium speed was limited to 20 km/h (12.5 mph) but with a much higher traction force than the regular Eifel. They were powered by a 1.2l 34 bhp 4 cylinder engine. These cars were also converted from burning petrol to LPG. Those auxiliary tugs were used to tow available trailer or horse drawn carriages with furniture, food, coal etc.. In Aachen 8 of these Eifel were used by coal, potato and builder's merchant. The only existing vehicle is now locate in Automuseum PS-Specher, Einbeck/Germany.

Here a video

Translation of subtitle

0:10 – 0:30

During my walk around through the lorry department Bus and Blaulichttag at PS-Speicher. I recognize a very odd self made conversion of a Ford. I ask Bernd Günzel one of the volunteers at the Museum to show me the vehicle and give me some explanation. There is a very interesting story

Sign on Passenger seat: Ford Eifel Hilfsschlepper ( auxiliary tug) From 1940 on auxiliary axles were built for those Ford Eifel that were not drawn into military service during WW II. Those auxiliary tugs were used to tow available trailer or horse drawn carriages with furniture, food, coal etc.

Sign on dashboard: Attention while speaking! Enemy is listening!

1:25

Close the door

Sign on door: Short distance Hauling, Aachen

1:43 – 2:56

We got an interesting vehicle to our collection, a 1940 Ford Eifel which was original powered by 1.2 l 4 cylinder petrol engine. Due to the war hauling capacity by tugs and other vehicle was limited because most of these vehicle were confiscated by the military. Therefore an auxiliary frame was installed to this vehicle. A chain sprocket was attached to the brake drum to get a shorter ratio. The vehicle had a maximum speed of 20 Km/h (12.5 mph) but with a much higher traction force for this tiny engine. In addition the vehicle was converted to LPG. The system is not complete but from the technical principal present although not operable. The engine is still run, but driving has to be an acquired taste. Driving fun is missing.

2:56 – 3:16

Thank you Bernd for the explanation. It has to be mentioned that this is the only remaining auxiliary tug from a bitter time. In Aachen were 8 of the auxiliary tug used by coal, potato and builder’s merchant. This Eifel was build in Cologne with a 1.2l 34 bhp engine.

3:16 – 3:34

The triangle for tractor? Yes for trailer towing

Here a video

Translation of subtitle

0:10 – 0:30

During my walk around through the lorry department Bus and Blaulichttag at PS-Speicher. I recognize a very odd self made conversion of a Ford. I ask Bernd Günzel one of the volunteers at the Museum to show me the vehicle and give me some explanation. There is a very interesting story

Sign on Passenger seat: Ford Eifel Hilfsschlepper ( auxiliary tug) From 1940 on auxiliary axles were built for those Ford Eifel that were not drawn into military service during WW II. Those auxiliary tugs were used to tow available trailer or horse drawn carriages with furniture, food, coal etc.

Sign on dashboard: Attention while speaking! Enemy is listening!

1:25

Close the door

Sign on door: Short distance Hauling, Aachen

1:43 – 2:56

We got an interesting vehicle to our collection, a 1940 Ford Eifel which was original powered by 1.2 l 4 cylinder petrol engine. Due to the war hauling capacity by tugs and other vehicle was limited because most of these vehicle were confiscated by the military. Therefore an auxiliary frame was installed to this vehicle. A chain sprocket was attached to the brake drum to get a shorter ratio. The vehicle had a maximum speed of 20 Km/h (12.5 mph) but with a much higher traction force for this tiny engine. In addition the vehicle was converted to LPG. The system is not complete but from the technical principal present although not operable. The engine is still run, but driving has to be an acquired taste. Driving fun is missing.

2:56 – 3:16

Thank you Bernd for the explanation. It has to be mentioned that this is the only remaining auxiliary tug from a bitter time. In Aachen were 8 of the auxiliary tug used by coal, potato and builder’s merchant. This Eifel was build in Cologne with a 1.2l 34 bhp engine.

3:16 – 3:34

The triangle for tractor? Yes for trailer towing

Pictures fetched from https://www.imcdb.org/v001129235.html

France Assembly

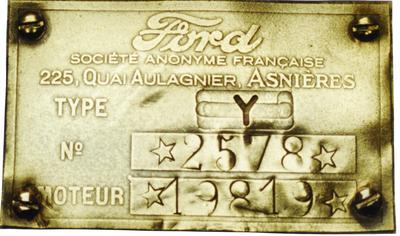

6CV Model “Y”. January 1933 – Late 1934

Because of the high tariff barriers between European countries in the early 1930s, the price of the Model “Y” in France was significantly higher than the equivalent national makes (Citroën, Peugeot and Renault). Consequently only about 4000 6CV Model “Y”s sold over a relatively short production period. The youngest known surviving “Y” carries Asniéres assembly number 3898 (Y64982 – June 1934). Asniéres assembled cars can be identified by the brass plaque screwed to the bulkhead under the battery box. The L.H.D. imported CKD saloon (‘coach’ in French parlance) incorporated a number of in-country produced parts, such as the upholstery, trim, glass for windows, etc. Many attractive bodies were built onto imported rolling chassis at Ford S.A.F., Asniéres to stimulate demand. Société Industrielle de Carrosserie Automobile de Levallois (SICAL) produced both a fixed head and a drop head coupé; Duval a smart roadster and Kelsch a Tudor coach (saloon), a cabriolet, a fixed head coupé, a Tudor coach with rear ‘commercial’ access (similar to the English Jennings conversion), a roadster and a van (‘fourgonnette’). The Kelsch models are easily identified by the raised coachwork behind the scuttle adding about three inches overall to the width of the body tub. A private venture by a member of the French Ford Board of Directors produced two prototype front-wheel-drive Model “Y” ‘Tracfort’ variants for the 1934 Paris Salon, the 'Tourisme' and the 'Sport'. Although 12 prototype display cars were made, the company went into liquidation before any commercial production could begin.

The 6 CV indicates a fiscal horsepower (Cheval Vapeur) rating of 6, based on a quite different French fiscal formula. There is no evidence of Model “C”s or “CX”s being assembled in France.

The 6 CV indicates a fiscal horsepower (Cheval Vapeur) rating of 6, based on a quite different French fiscal formula. There is no evidence of Model “C”s or “CX”s being assembled in France.

Asnières assembly plate riveted to bulkhead below battery box

Model “Y” fixed-head-coupé bodied by SICAL

Model “Y” roadster bodied by Duval

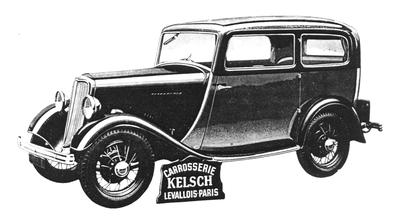

Kelsch bodied ‘coach’ (saloon)

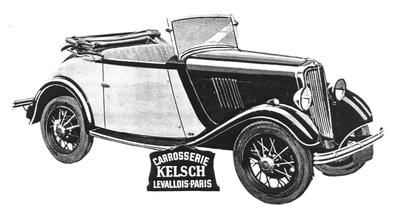

Kelsch bodied cabriolet

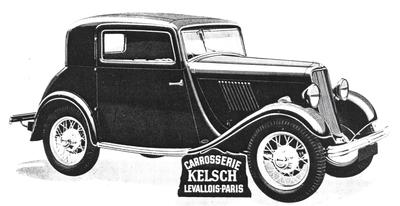

Kelsch bodied coupé

Kelsch bodied roadster

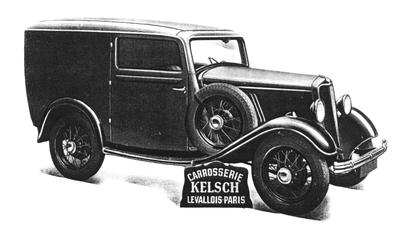

Kelsch bodied ‘fourgonnette’ (van)

Prototype Tracfort ‘Tourisme’

Prototype Tracfort ‘Sport’

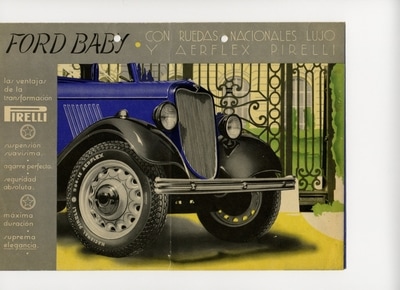

Spain Assembly October 1932 – July 1936 (Outbreak Of Spanish Civil War)

Modelo 8 (Model “Y”)

Model “Y” assembly was continuous throughout the period, until strikers sympathetic to the Republican cause took over the Ford factory in Barcelona in July 1936, when production ceased. Apart from locally procured items such as upholstery, trim, glass, etc., the Barcelona Model “Y”s were the same as the Dagenham products, the cars having been imported in CKD condition from England. For a period at the beginning of the long rad production, the Spanish cars were fitted with surplus short rad bumpers, until these were used up. Some cars were fitted with a crude aluminium plate under the battery box recording the chassis number. In early 1936, in order to increase Ford of Germany's exports and thus appease Hitler, Ford Ibérica was told by Ford in London to buy some components from Cologne. It is likely that some Dagenham/Cologne hybrid cars were manufactured before the onset of the Spanish Civil War later that year. During the war, many cars were commandeered by members of both sides of the conflict and kept on the road by cannibalisation and bodging. After the War, cars that had no documentation were re-registered and carried a re-registration plate.

Pirelli's Spanish branch offered 'Easiclin' wheels for the Modelo 8

Modelo 8 Tourers

Different Spanish bodied tourers at the 1933 Barcelona exhibition

At the 1933, 6ª Expositión del Automóvil de Barcelona, appeared two cabrio limousines and two tourers marketed by Amado Casajuana, the main Ford dealer in Barcelona. The coachbuilder could well have been Ramón Pla, who shared the stand. None of the cars is thought to have survived.

Modelo 8 Vans

Two distinct van designs appeared on the Model “Y” chassis in 1934 and 1936 respectively. The coach builder is unknown. None is known to have survived.

1936 larger capacity van bodied in Barcelona

Modelo 10 (Model “C” And “CX”) – December –July 1936

Hybrid 1936 Modelo 10 with Ford Köln components

The first left hand drive Model “C” was manufactured at Dagenham on 11 December 1934. It is therefore assumed that the export of CKD cars to Barcelona started at that time. As with the Model “Y”, apart from some in-country procured items, the cars were the same as the Dagenham products. Also, as with the Model “Y”, German components were procured in 1936 with Spanish cash currency to obtain German Mark exchange to help the Cologne factory’s export rating. This was sensible as German had a trade deficit with Spain due to its import of raw materials and minerals. Hybrid Model “CX”s appeared in 1936.

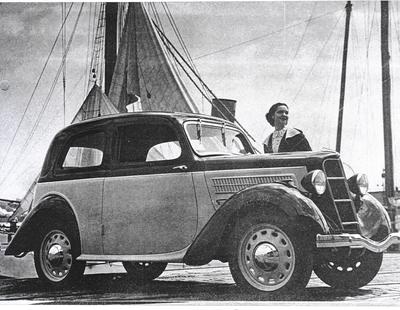

Denmark Assembly

October 1932 – August 1937

Copenhagen assembly plate on bulkhead above tool box

The Ford Motor Company A/S, Copenhagen, supplied Ford vehicles to much of Scandinavia (less Sweden and Finland) and Poland under the names Ford Junior (Model “Y”) and Ford Junior De Luxe (Model “C”/“CX”). As with other European countries, because of the tariff barriers, locally procured material was incorporated into the CKD vehicles imported from Dagenham. A similar arrangement with Ford’s Cologne factory as with Ford Ibérica was instituted in 1936, whereby German built cars were supplied to Copenhagen to help Ford Cologne’s export figures. Copenhagen assembled vehicles can be identified by the assembly plate on the bulkhead.

Un-restored Danish Ford Junior De Luxe cabrio-limousine

Sales To The British Empire

To take advantage of the lower tariffs between British Empire countries, the Ford Motor Company of Canada was awarded the franchise for the supply of Ford vehicles throughout the Empire. All orders for vehicles were placed on Ford of Canada in Windsor, Ontario, across the Detroit River from Dearborn, and Fords destined for the Empire countries were shipped from there, other than the small Fords and other vehicles built solely at Dagenham which, on instructions from Windsor, were shipped direct from the jetty at Dagenham. Models 'Y' and 'C'/'CX' were shipped from Dagenham in a Built Up state, other than to Australia, India, Malaya, New Zealand and South Africa, which had their own assembly plants and received the vehicles in crates in a CKD (Completely Knocked Down) state. Indigenous variations to body design appeared in Australia and, in the case of the Model 'C' van, in New Zealand.

Australia Manufacture And Assembly

Model “Y”. June 1933 – 1936

Because of the classification of complete cars as luxury goods during the First World War and hence exorbitant import duties being charged, a thriving indigenous coachbuilding industry grew up and all Australian cars had bodies built in-country on imported running chassis. Hence the Ford Motor Company of Australia Pty., when built on the harbour-front at Geelong, Victoria, in 1925, incorporated a body building company, the Ford Manufacturing Company of Australia Pty. Their brilliant young designer, Lew Bandt, was responsible for a number of different body styles suited to the rough Australian roads, the weather and the lifestyle. All sedans (saloons) were Fordor models. Assembly plants were also built in Adelaide, South Australia; Fremantle, Western Australia; Brisbane, Queensland and Sydney, New South Wales.

Model “Y” June 1933 – 1936

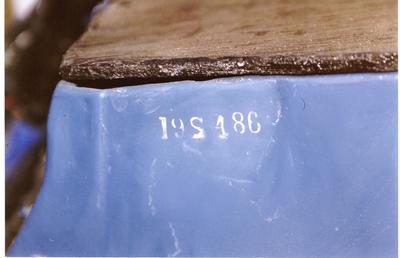

The first CKD rolling chassis did not arrive in Australia until June 1933, nine months after the launch of the Model “Y” in England. Six different body styles were built on to the chassis, each with its distinctive body number; sedan (standard and de luxe) – 19S … , Coupe (de luxe) – 19C … , Phaeton (standard and de luxe) – 19P … , Roadster (standard and de luxe) – 19R … , Utility (straight side and well side) – 19LD … , Panel van – 19PD. Note, LD stood for Light Delivery and PD, Panel Delivery. The body style number, followed by the batch number, was hand-stamped on the left hand end of the tool box. e.g. 19PD 42 was the 42nd Panel van assembled. The early long rads had short rad bumpers. Few Model “Y”s were sold after the introduction of the Model “C”, which was better suited to the Australian environment.

Sedan

As stated, these were all Fordor models, looking the same as the Briggs bodied English cars. “Y” sedan body no: 19S 480 on side of toolbox.

Model “Y” coupe (19C …) – De Luxe had ‘dicky’ seat

This was a two-door, two-seater hard top car with either a luggage boot (Standard) or a ‘dicky’ seat (De luxe). There were no quarter windows behind the doors. Model “Y” coupe (19C …).

Model “Y” phaeton (19P …): 4-door, four seater

Phaeton: A Fordor, four-seater open topped car with large fold-away hood.

Model “Y” roadster (19R …) – De Luxe had ‘dicky’ seat

Roadster: Similar concept to the coupe with both Standard and a De luxe bodies, but with a foldaway soft top.

Model “Y” well-sided Ute (19LD …) in New South Wales

The 'utes' were officially known as ‘roadster utes’ with a similar soft topped cab to the Roadster, but with a load carrying area behind the cab. These were either straight-sided or well-sided, the well sided utes having a protruding platform along the sides of the load-carrying area.

Model “Y” van (19PD …)

Panel van: Similar to the Dagenham-built Model “Y” van. None is known to have survived.

Panel van: Similar to the Dagenham-built Model “Y” van. None is known to have survived.

Model “C” And “CX”

The “C” and “CX” body numbers were hand-stamped on the left hand end of the tool box.

These were sold in much greater numbers. As with the Model “Y”, the Model “C” body styles and body numbers were:- Sedan – 20S … , Coupe – 20C … , Roadster – 20R … , Utility (straight sided and well-sided) – 20LD … and Van – 20PD … The Model “CX” body numbers carried a letter ‘B’ after the 20, e.g. Sedan – 20BS … . A “CX” Phaeton was produced (20BP … ), although it seems identical to the English Model “CX” tourer, but with external door handles; only two seem to have been manufactured of which one (20PB 2) survives.

These were sold in much greater numbers. As with the Model “Y”, the Model “C” body styles and body numbers were:- Sedan – 20S … , Coupe – 20C … , Roadster – 20R … , Utility (straight sided and well-sided) – 20LD … and Van – 20PD … The Model “CX” body numbers carried a letter ‘B’ after the 20, e.g. Sedan – 20BS … . A “CX” Phaeton was produced (20BP … ), although it seems identical to the English Model “CX” tourer, but with external door handles; only two seem to have been manufactured of which one (20PB 2) survives.

Model “CX” coupe (20BC …)

All Model “CX” coupes and roadsters were De Luxe and had ‘dicky seats.

Model “CX” roadster (20BR …)

Model “C” straight-sided utility (‘ute’) (20LD …)

Model “C” well-sided ute (20LD …)

Model “C” van (20PD …)

Model “CX” phaeton (tourer) (20BP …)

Similar to Dagenham Model “CX” tourer but with door handles.

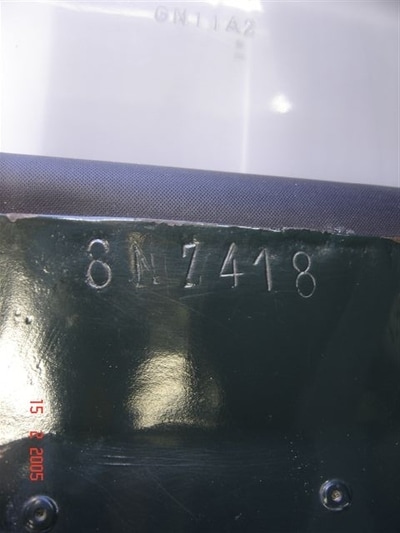

New Zealand Assembly

The Colonial Motor Company Ltd., based in Wellington, held the Ford franchise in New Zealand from 1908. In 1922, the company built an assembly plant, which assembled CKD vehicles imported from Dagenham until November 1936, when the Ford assembly plant opened at Lower Hutt on the outskirts of Wellington. The New Zealand vehicles were identical to the Dagenham ones, except that from November 1936, Ford assembled vehicles carried a hand stamping on the front of the battery box. The numbering system seemed to settle down to a logic of 8NZ … for the Model “Y” and 10NZ … for the Model “CX” assembly. The Colonial Motor Company commissioned Standard Motor Bodies Ltd. to build a van body for the Model “C”/ “CX” rolling chassis.

Lower Hutt Ford plant assembly number on battery box

Model “C” van bodied by Standard Motor Bodies Ltd